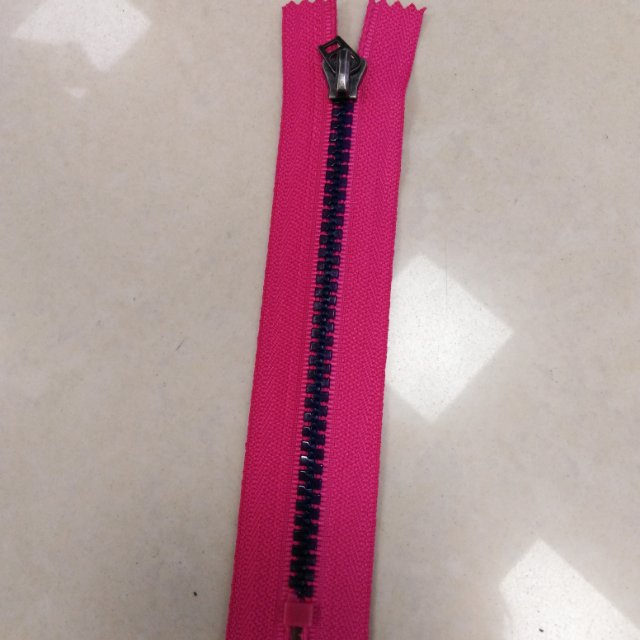

In everyday life, zippers are inconspicuous but ubiquitous. In particular, the classic style of 5-size closed tail zipper is favored for its excellent performance and wide range of applications. Today we will learn more about the core structure, functional characteristics of this product and how to choose the most suitable high quality zipper.

First, let's talk about its internal structure. This type of zipper consists of a head, a rack part and a bottom part, of which the most critical part is the small but extremely important closed end design. Such a setting can prevent the article from slipping off while also increasing the overall firmness. Therefore, it is very suitable for applications in backpacks, suitcases and even outdoor equipment.

With the changing market demand, the requirements of different industries for zippers are gradually refined. For example, fashion brands pursue light, flexible and easy to open and close versions; while mountaineering enthusiasts prefer strong, durable and corrosion-resistant products. Therefore, it is particularly important to make a clear selection of specific uses.

so how can we identify the real quality products? the appearance of observation whether there are obvious burrs or cracks is a basic standard. In addition, you can also test its smoothness by hand feeling, and try to pull it several times to see if there is a Caton phenomenon. Weight is also a consideration-too light may mean not strong enough, too heavy may reduce comfort.

Let's talk about materials. At present, the mainstream use of the market is mainly two kinds of raw materials: zinc alloy and plastic. The former has good wear resistance and oxidation resistance, suitable for high-end manufacturing links; the latter is low cost and rich in color and easy to shape, it is more common in ordinary consumer goods. Of course, there are other special cases in which stainless steel or other compounds are used.

To verify the truth of these claims, let's look at a few specific examples. A well-known sneaker manufacturer has conducted a durability test for more than two years on a model used in its production line. The results showed that even after more than 100,000 opening and closing movements, the company remained in good condition and found no obvious signs of damage.

Finally, it is worth mentioning a new trend that has emerged in recent years-personalized customized services. If you happen to belong to those friends who need special specifications or styles, you may wish to consider contacting professional manufacturers for detailed requirements. They can adjust the length, color and even additional pattern text identification according to customer needs.

In addition to the early stage selection, the later maintenance can not be ignored. Regular cleaning to remove dirt and foreign matter can help extend service life. When encountering problems that are difficult to solve, do not force the operation to avoid secondary damage. Instead, you should seek professional help.