Exquisite details: the charm of a 5-size closed-end zipper pull

Although zippers are small, they play a vital role in the design of clothing and bags. In particular, the 5-size closed tail zipper head has become the first choice of many high-end brands with its unique structure and exquisite craftsmanship. This kind of zipper head not only improves the quality of the finished product, but also prolongs the service life to a great extent. This article will delve into its uniqueness and why it is a key element of quality improvement.

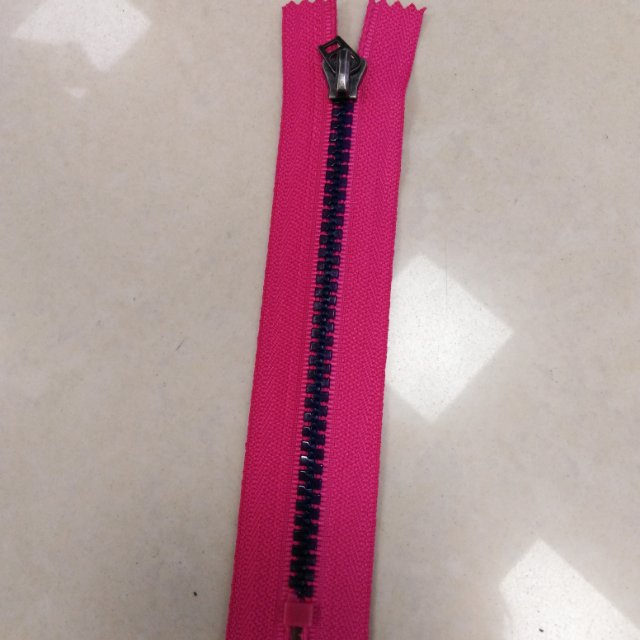

Exquisite 5 Size Closed Tail Zipper

Exquisite 5 Size Closed Tail Zipper

The high quality 5-size closed-end zipper pull is not just a simple opening and closing tool, but a work of art. Every part of it is finely polished and rigorously tested to ensure that every pull is smooth and durable. Not only that, it can also be perfectly integrated into various designs, adding a distinctive charm to your products.

Accurate matching needs: how to choose the most suitable zipper type

in the face of the dazzling array of zipper options on the market, how can you choose the most suitable product for your project? we will analyze the impact of different materials, colors, lengths and other factors on the final effect, and give practical cases for readers' reference. Whether it is a fashion item or outdoor equipment, the right choice can make your work stand out and show your personality and professional standards.

The first thing to consider is the application scenario. If you are making high fashion or limited edition handbags, zinc alloy zippers with strong metallic texture may be the best choice; for daily wear or sports backpacks, lightweight and wear-resistant nylon or polyester materials are more ideal. In addition, color matching is also crucial-black classic atmosphere, silver simple fashion, color is lively and bright... According to the overall style to determine the most appropriate color combination.

Examples of zippers in different materials and colors

Examples of zippers in different materials and colors

In addition to the factors mentioned above, there are two aspects that need attention: one is the width of the zipper (that is, the pitch), which determines the size of the opening after the pull; the second is the end treatment (such as flat, ring, etc.). Both of these will directly affect the use experience and appearance. Therefore, it is important to carefully measure the parameters before purchasing, and strive to achieve the optimal configuration.

Perfect integration of aesthetics and function: analysis of the advantages of closed tail design

The closed tail gives the zipper a whole new life-both beautiful and functional. This section details the principles behind such designs and the benefits they bring, such as preventing accidental opening and increasing safety. Through the example display and data support, reveal why the closed tail zipper head can emerge in many competitors.

The head of the traditional open zipper is prone to loosening, especially the risk of damage or even loss of items during frequent opening and closing. In contrast, the zipper with a closed end adopts an integrated molding technology to form a complete sealing ring in the closed state, which effectively prevents foreign objects from entering the internal cavity and greatly improves the tear resistance. In this way, users can safely enjoy the convenience without worrying about any potential threats.

closed-tail zipper design for added security and durability

closed-tail zipper design for added security and durability

More importantly, this design makes the whole zipper look more neat and unified, and no extra parts are exposed, giving people a delicate and high-end feeling. In particular, some attention to detail of the brand, in the pursuit of the ultimate perfect on the road will not let go of any corner. So when you see those amazing works in the market, please don't be surprised that the hidden secret weapon is such an inconspicuous but indispensable small part!

Easy operation and worry-free maintenance: installation and maintenance strategy

It is important to have high-quality accessories, but if you do not know how to use and maintain them correctly, you may get twice the result with half the effort. Detailed step-by-step guidelines and practical tips are provided here to teach you how to complete the installation efficiently and ensure good condition for a long time. From daily cleaning to troubleshooting, all relevant knowledge points are covered to help you.

First, there are recommendations for installation. In order to make the new zipper work smoothly and not easy to deform, it is best to soak it in warm water for about ten minutes before sewing and fixing. Doing so softens the material fibers to make it easier to shape and reduce frictional resistance. After that, according to regular method, the two pieces of fabric can be spliced together.

as for future nursing measures, they mainly include regularly wiping dust and stains on the surface to prevent rust and corrosion; Avoid contact with sharp objects to avoid problems such as scratching, scratching, and peeling of the surface coating. In case of Caton, do not drag by force, but check the cause patiently and fix it according to the remedy. In short, following scientific and reasonable practices can keep your baby in a bright and beautiful state ~

The Story Behind Ingenuity: Revealing the Secret of the Manufacturing Process

Behind every high-quality zipper is the brainchild of countless craftsmen. Through the lens, we lead everyone into the factory and witness every link in the whole process from raw material selection to final assembly. Understand how advanced production equipment and technical means ensure consistent product quality and feel the attitude of excellence.

On the entire production line, the first step is to screen and classify the raw materials. Only the copper and aluminum wires that meet the standard requirements and pass the inspection will be sent to the furnace for heating and melting to make the required metal blanks. Then the use of mold stamping forming to get a preliminary contour and then through a series of precision machine cutting drilling and other processes to shape. Then came the assembly stage, which tested the most technology and experience-the workers carefully nested and assembled the parts one by one with the skillful techniques accumulated over the years until a complete and usable product was formed.

The final step is quality control. Each batch